Our Raw Chocolate

The difference between "conventional" and our raw chocolate products lies in both the taste and the natural power of its main ingredient: the cacao, mother of all superfoods. Thanks to the completely different way of making the product, our raw chocolate lets you experience the authentic taste of cacao while its wonderful natural nutrients are treated respectfully, too.

Conventional Chocolate Production

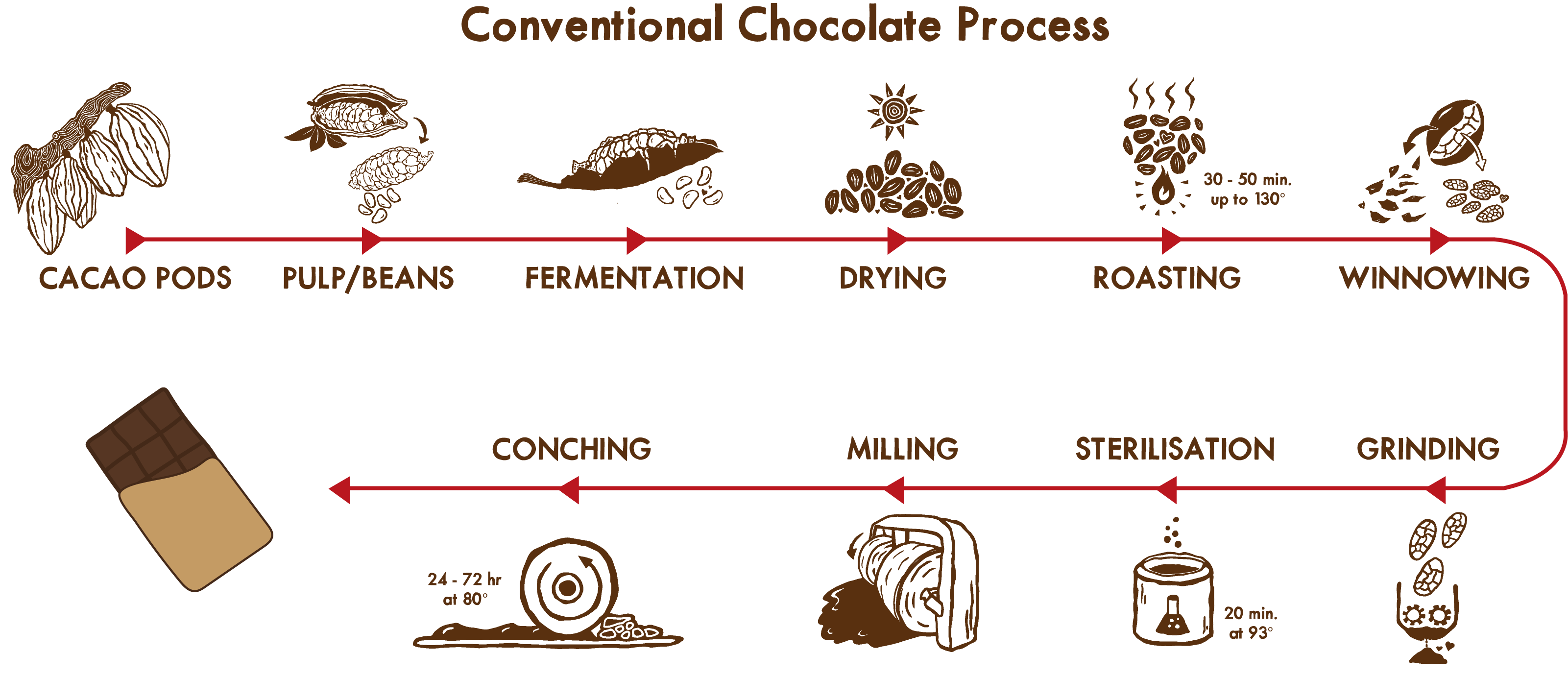

To understand the difference, let`s start with a little introduction to conventional chocolate production and then compare it to our raw chocolate making. The conventional chocolate process can be divided into 10 steps:

The chocolate making process starts with harvesting ripe cacao pods from the tree (1), opening them to get the fruit pulp covered beans out of the pod (2), and then place these beans into wooden tubs covered with banana leaves to ferment. This process can take between 3-5 days depending on the season (3). The beans are then dried in the sun or a shaded space (4), after which they are usually roasted at high temperatures for about 30-50 minutes (5), then cracked/winnowed to separate the outer shells from the beans (6). Now, the cacao nibs are ready for grinding into cacao mass (7). Afterwards, the cacao mass or paste is ususally sterilized with hot steam or even chemically (8). The 2 final stages are milling (usually together with the sugar, cacao butter and milk) (9) and conching for up to 72 hours (10) to make the chocolate smooth.

This whole procedure delivers the smooth melting, sweet product you know as chocolate. But just like when you overcook your vegetables, the natural power of the raw cacao gets lost when it is strongly roasted, sterilized, milled and conched. At Lovechock, we have chosen to do things differently and make RAW chocolate. That means we take out a lot of those steps because we believe food is better when you keep it close to nature, pure, real and raw.

Making Our Raw Chocolate

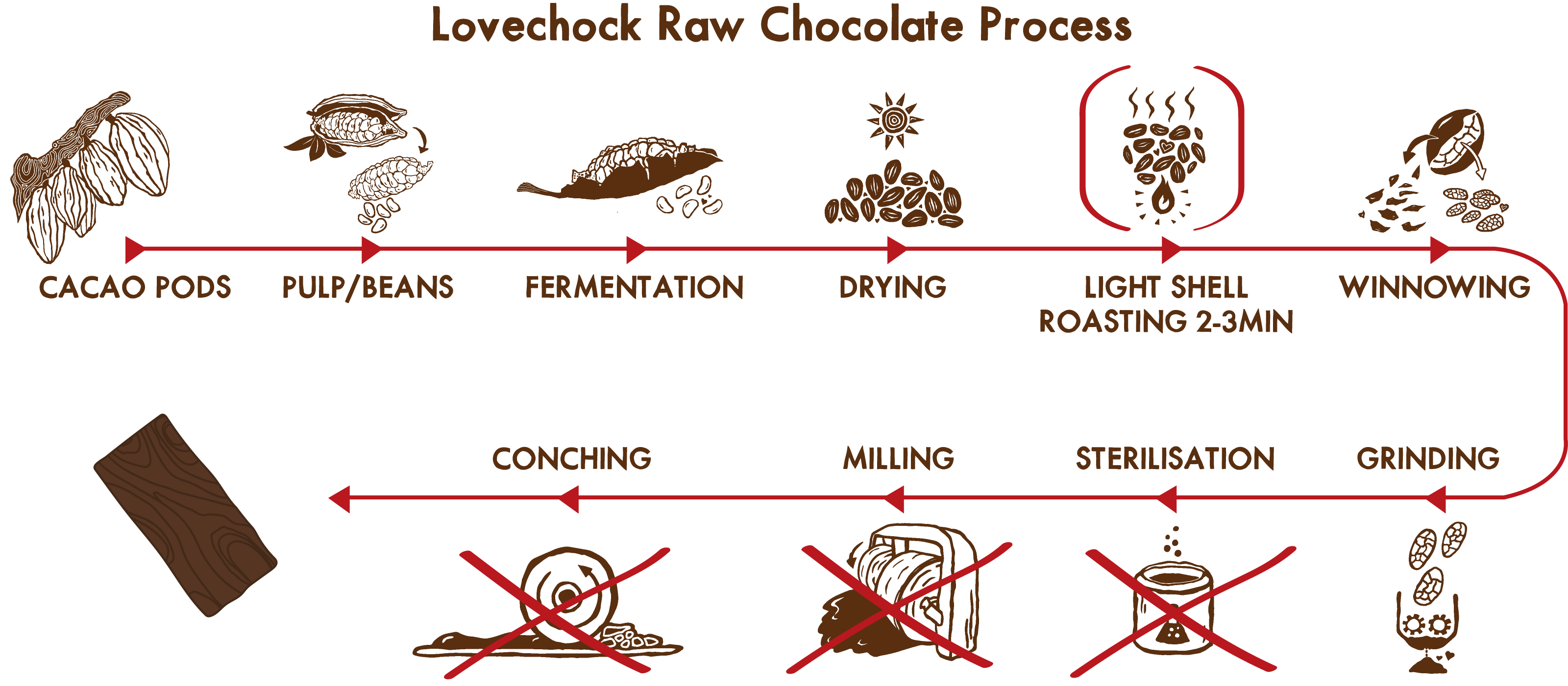

Lovechock does a few things deliciously different in making its raw chocolate to harness the power of raw cacao:

Contrary to regular cacao production processes we only lightly and quickly roast our beans for food safety, keeping the core nice and raw. We completely cut out the sterilisation, milling and conching steps. Lovechock’s raw cacao is treated as little as possible out of respect for its unique authentic taste and healthy natural nutrients such as minerals, vitamins and flavonoids.

While strong roasting can be used to improve the flavour profile even of lower quality cacao beans, we choose only the best cacao from Ecuador and Peru because we do not want to resort to such measures. Our high quality beans naturally have a wonderful fruity and floral taste. During fermentation the beans are turned often to avoid high fermentation temperatures, allowing the sweet pulp to be absorbed by the bean to create a deliciously full, fruity, floral, rich cacao taste. After short and light shell roasting (5), the beans are separated from their outer shell during winnowing (6) and then ground finely (7) into cacao mass from which we make our signature tablets and bars.

By low processing we preserve the unique flavour and nutrients of our raw cacao. We then add just a little bit of coconut blossom nectar and a variety of delicious natural superfoods to deliver Lovechock’s Raw Goodness!